Why you should think of your Supply Chain as a System?

- by Paul Kelly

- •

- 24 Jan, 2019

Supply chains are too complex to think about as anything other than human activity systems. Systems thinking and systems leadership are required to solve the supply chain issues of 2020.

In his international bestseller on organisations (Images of Organizations) Gareth Morgan discusses the metaphors we use to understand organisations. In it, he talks about metaphors such as machines, brains, cultures and organisms. Much of the research that he reflected on has now entered mainstream thinking. Concepts such as The Learning Organisation and the importance of culture are now commonplace. The move away from command and control thinking is now regarded as best practice.

But what of our approach to Supply Chains and Supply Chain Management?

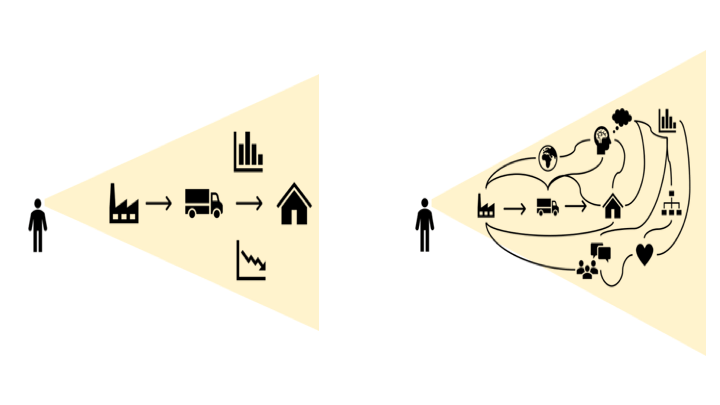

Here it seems we have not yet moved away from the machine metaphor. In this metaphor, we reduce supply chains to a series of nodes and 3rd parties. Supply networks (a nod to the complexity of modern supply chains I grant you) are there to be analysed and optimised. This perspective is based on an engineering mindset. A supply chain is something that can be designed, built and operated as if it were a machine.

Supply chains can be engineered to deliver!

In this metaphor, spreadsheets, inventory models and metrics provide our visibility and insight. The number and variety of SKUs is the first piece of information we ask for! Cost-to-serve models and analytics on the flow of goods dominate discussions on supply chain strategy. Where we mention people, it's usually in the context of overcoming resistance to change or as the consumer.

All these perspectives are of value of course. They can help us to understand aspects of an end-to-end supply chain, but they do not tell the full story.

What is missing is a recognition that any model of a supply chain that reduces it to a spreadsheet or a process flow (a chain) hides much of its complexity. It masks the underlying unpredictability we all know as our day-to-day reality.

So instead of thinking about our supply chains as chains or networks, we need to start thinking about them as systems.

They have all the characteristics of a system including:

· they are complex

· they depend on different parts of it interacting with each other

· they operate within a wider environment

· each serves a purpose (or purposes)

To all intents and purpose, a supply chain is a supply system.

We should also recognise what type of system it is. It is not a machine or a computer system, or even a system of sheds, inventory and transportation. A supply system is a human activity system.

It contains people working in teams and organisations. These people do what humans do – theorising, making decisions and acting. Everything that drives a supply system comes from people acting (or not acting) with a purpose.

Consider the supply chain that ensures your local supermarket is stocked with fresh produce. How many different suppliers, organisations, countries, teams and people are involved? Consider each separate operation and how they interact with each other and with their environment? How easy is it to map in a sequential process flow once the detail of what really happens is understood? Does it look like a simple chain or does it feel like a complex system?

What are the implications of thinking in this way?

First, we can begin to understand why we experience complexity and uncertainty. We can also start to appreciate the importance of the different views and perceptions that people might have. We can begin to recognise why alignment is so often a challenge, and why cultural differences are so important.

Once we start to adopt a systems thinking mindset then managing the supply system takes on a different complexion.

It can open our eyes to different ways of seeing what is really going on. It should encourage us to consider different stakeholders and different perspectives. At a more fundamental level it should help us to ask not just the ‘where’ and the ‘how much’, but also the ‘why’. From a systems thinking perspective, this doesn't mean asking why in terms of who is to blame. Rather, asking why at a more profound level. For example, what is happening in the system to cause inventory to be stored in specific locations and quantities?

In this context, the Supply Chain Manager should be more appropriately called a Head of Supply Systems. The executive role would be the CSSO (Chief Supply System Officer).

With a systems thinking lens, the complexity does not go away. However, a Systems Leader will acknowledge and embrace it. They are likely to adopt different tools and methods to supplement traditional analysis. By thinking systems not chains they will help those working in the system to understand better how to discover, develop and deliver new ways of working. Making changes with a systemic perspective is likely to be more successful. You can address Chronic issues with more confidence that solutions will be found. More importantly, a systemic approach that recognises and involves all stakeholders will ensure that the changes you implement will be feasible and sustainable.

The challenges facing Supply Systems in 2020 will demand systemic solutions. The time for Supply Systems Leadership is now.

If you've found this article useful please ‘like' or ‘share' so it can help others too. If you want to chat more about systemic leadership in supply systems, give me a call.